The Science Behind Defoamers and Their Role in Foam Control

The Science Behind Defoamers and Their Role in Foam Control

Blog Article

Picking the Right Defoamer for Your Particular Application Requirements

Choosing the suitable defoamer for certain application requirements is a nuanced process that requires cautious consideration of multiple aspects, such as the foam medium, type, and operating conditions. Comprehending the subtleties of defoamer efficiency-- consisting of speed and persistence-- while also making up ecological and regulatory factors is crucial. In addition, engaging in tests and consulting with suppliers can offer valuable insights. Nonetheless, navigating these intricacies can be difficult, and the consequences of a bad selection may be significant. What approaches can be employed to guarantee an optimum selection?

Recognizing Foam Development

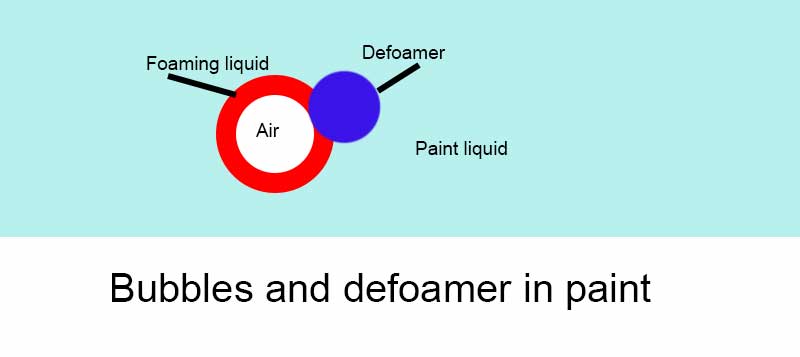

Foam formation occurs when gas is caught within a fluid, developing a secure structure of bubbles. This phenomenon can substantially influence numerous commercial procedures, specifically in sectors such as food production, pharmaceuticals, and wastewater treatment. The existence of foam can impede mixing, minimize product top quality, and also bring about functional ineffectiveness.

Foam typically creates because of a mix of variables, consisting of surface-active representatives, frustration, and the characteristics of the liquid phase. Surfactants lower the surface area stress of the liquid, assisting in the development of bubbles that can stabilize and coalesce. Agitation, whether from mechanical mixing or gas intro, enhances bubble development, bring about increased foam quantity.

Recognizing the technicians of foam development is vital for markets aiming to maximize their procedures. By determining the specific problems that advertise foam generation, organizations can implement approaches to minimize its impacts. This understanding lays the groundwork for selecting ideal defoaming agents that effectively target the one-of-a-kind difficulties positioned by foam in various applications. As a result, an extensive understanding of foam development is necessary for enhancing performance and preserving product stability across different sectors.

Kinds Of Defoamers Available

Numerous kinds of defoamers are readily available to deal with the obstacles positioned by foam in industrial applications. defoamers. Extensively identified, defoamers fall into three classifications: silicone-based, non-silicone-based, and all-natural defoamers

Silicone-based defoamers are renowned for their effectiveness and stability across a vast range of temperatures and pH levels. They are commonly used in applications where strong foam reductions is needed, such as in finishings, adhesives, and paints. Their low surface area stress permits for rapid foam collapse.

Non-silicone-based defoamers, frequently made from natural substances, supply an alternative for applications conscious silicone residues. These defoamers can be additional split right into polyether and ester kinds, each customized to satisfy details formulation requirements. Non-silicone defoamers are often utilized in food processing and personal care products because of their compatibility with different formulas.

All-natural defoamers, originated from plant or pet resources, are obtaining grip as a result of their environment-friendly account. These products are especially appealing in applications where regulatory compliance and sustainability are vital, such as in agrochemicals and biotechnology.

Selecting the right type of defoamer is essential for optimizing performance and ensuring compatibility with specific applications.

Key Application Factors To Consider

When picking a defoamer, it is vital to take into consideration the specific application requirements to make certain ideal performance. defoamers. Various sectors have unique needs, such as food handling, pharmaceuticals, or wastewater therapy, and each application might require unique defoaming residential or commercial properties

Trick aspects to assess consist of the tool in which the defoamer will be used, whether it is water-based, oil-based, or a mix thereof. The temperature and pH degrees of the application can likewise greatly affect the efficiency of a defoamer. In addition, compatibility with various other chemicals present in the system is crucial to avoid damaging reactions that can endanger efficiency.

One more vital consideration is the foaming actions of the certain system. Understanding whether the foam creates promptly or gradually can guide the choice of a defoamer that targets the source efficiently. The wanted speed of defoaming can influence the option, as some applications call for rapid action while others might endure slower defoaming processes.

Finally, ecological and regulatory factors to consider ought to not be forgotten, particularly in markets with rigorous conformity requirements. Choosing a defoamer that lines up with these variables guarantees both effectiveness and safety in the application.

Performance Testing Methods

Evaluating the efficiency of a defoamer needs a methodical method to testing that accurately measures its performance in specific applications. Numerous efficiency screening techniques can look at this website be utilized to determine the optimal defoamer for a given formulation.

One common approach is the bubble examination, which examines the defoamer's capability to decrease foam quantity in time. This test involves generating a secure foam and then adding the defoamer to observe the price of foam collapse. One more technique is the vibrant foam test, where foam is generated under regulated conditions to imitate real-world application situations. This approach offers understandings into just how the defoamer carries out under differing shear problems.

Inevitably, picking the appropriate efficiency screening approach relies on the particular application and the sort of foam being dealt with. Each technique provides useful data that can direct formula adjustments and enhance the effectiveness of the defoamer in practical applications.

Finest Practices for Choice

Following, take into consideration the defoamer's performance in terms of speed of activity and perseverance. A quick-acting defoamer may be essential for processes where fast foam reductions is important, while an extra relentless formulation could be required for long term foam control. In addition, assess the ecological impact of the defoamer, including its biodegradability and any regulatory compliance requirements.

Conduct trials with chosen defoamers to identify their efficiency in real-world conditions. This action is crucial to confirm that the chosen product fulfills efficiency expectations. Lastly, talk to suppliers or vendors for technical support get redirected here and advice, as they can supply useful insights right into item formulas and application techniques. By adhering to these ideal methods, you can improve foam control efficiency and make certain the durability of your procedures.

Conclusion

In recap, choosing the appropriate defoamer demands a thorough analysis of various variables, including foam kind, medium, operating problems, and environmental factors to consider. Understanding the special qualities of foam development and the readily available defoamer choices is crucial. Additionally, employing reliable efficiency testing approaches and sticking to ideal methods during the option procedure will certainly boost the possibility of attaining optimal defoaming results. Eventually, an educated selection method will certainly resolve particular application demands and minimize foaming difficulties properly.

Selecting the suitable defoamer for details application demands is a nuanced process that demands cautious factor to consider of numerous factors, such as the foam medium, type, and operating conditions.Choosing the right defoamer is critical for achieving optimal efficiency in foam control applications. Get the facts A quick-acting defoamer might be required for processes where rapid foam reductions is critical, while an extra relentless formula could be needed for prolonged foam control.In recap, picking the suitable defoamer necessitates a detailed assessment of various factors, consisting of foam type, medium, operating problems, and environmental factors to consider. Recognizing the special qualities of foam formation and the readily available defoamer choices is essential.

Report this page